product description

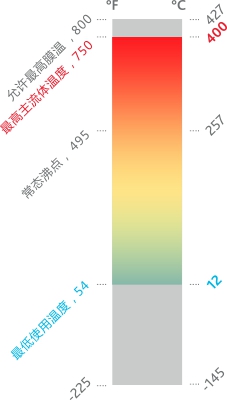

JY400 is a synthetic heat transfer oil designed for 12℃-400℃ liquid phase heating system or 257℃-400℃ gas phase heating system. Its important characteristics are as follows.

Excellent heat transfer performance - JY400 is a synthetic heat transfer oil with excellent thermal stability and low viscosity at the same time. It can provide effective, reliable and consistent performance in a wide temperature range of 12℃-400℃ . JY400 has high thermal stability in all organic heat transfer media.

Gas-phase heat transfer medium - JY400 is a eutectic mixture composed of 26.5% biphenyl and 73.5% diphenyl ether. It can be used as a liquid-phase heat transfer oil, and can also be used as a gas-phase heat transfer oil in the temperature range of 257℃-400℃ by taking advantage of its evaporation-condensation characteristics.

Low viscosity - JY400 still has a very low viscosity at the lowest temperature of 12℃. However, considering that it will crystallize below 12°C, measures must be taken to prevent operation problems caused by crystallization when used in colder climates.

Excellent temperature control performance ——Because JY400 can be used as a gas phase heat transfer oil, it can meet the requirements of a precise temperature control heat transfer oil system.

Scope of application

JY400It has been widely used in industrial fields, such as: chemical fiber industry; chemical industry.

If you want to know more about system design and application, please E-mail us or contact our sales representative .

Typical characteristics

JY400

Applicable temperature range of liquid phase: 12 ℃-400 ℃

Applicable temperature range of gas phase: 257 ℃-400 ℃

Exterior | Transparent, water white liquid |

Component | Biphenyl/diphenyl ether eutectic mixture |

Crystallization point | 12 ℃ |

Moisture | 300ppm |

Flash point | 124 °C |

Fire point | 127 ℃ |

Spontaneous ignition point | 621 ℃ |

Kinematic viscosity

40 ℃

100 ℃ |

2.48 mm 2 / S

0.99mm 2 / S |

Density (25 ℃) | 1060kg/m 3 |

Specific gravity (16 ℃ /16 ℃) | 1.069 |

Coefficient of thermal expansion (200 ℃) | 0.000979/ ℃ |

Volume shrinkage rate during solidification | 6.27% |

Volume expansion rate when melting | 6.69% |

Surface tension under contact with air (25 ℃) | 36.6dyn/cm |

Resistivity (20 ℃) | 6.4 × 1011 ohm-cm |

Average molecular weight | 166 |

Heat of fusion | 23.25kcal/kg |

Atmospheric boiling point | 257 ℃ |

Heat of vaporization at the highest operating temperature 400 ℃ | 206kJ/kg |

Best applicable range

Liquid phase

gas phase |

12-400 ℃

257-400 ℃ |

Allow the highest film temperature | 425 °C |

Quasi-critical temperature | 499 °C |

Quasi-critical pressure | 33.1bar |

Quasi-critical density | 327kg/m 3 |

The above data is for reference only, please refer to the requirements of "Organic Heat Carrier " GB 23971-2009 for specific indicators .

. For environmental protection, the health and safety of your employees and the purchasers of your products, you must make your own judgment to determine whether it is suitable for your application. The above content does not involve recommendations for any patent infringing products, processes, equipment or formulas. We do not make any explicit or implicit statements or guarantees regarding the use of these content that may infringe any patents. Regarding the materials or products involved in the materials, we do not make explicit or implicit statements or guarantees about their commercial availability, suitability for special purposes, and any other characteristics derived therefrom. The product safety data sheet provides safety precautions when using and storing our products, which you can obtain from us. You should obtain and read these safety information before using our products. If any of the materials mentioned is not our company's product, you should also follow the appropriate industrial hygiene and safety precautions recommended by the product manufacturer.