With the popularity of new energy vehicles, power batteries have not only become a key technology to reduce the overall price of vehicles, but also a major challenge to the environment in the next five years. According to the forecast of the China Automotive Technology and Research Center, in 2020, the amount of scrapped electric vehicle batteries will reach 120,000 to 170,000.

The lithium element in power batteries is evenly distributed globally, and China is in a leading position in the development of lithium resources. In terms of reserves, compared with South America, which has the richest resources, China has the second largest reserves in the world, with a total of 5.25 million tons, but in 2015 the consumption has reached 200,000 tons. The continuous consumption of lithium resources not only affects the sales price of power batteries, but also puts forward new requirements for battery recycling.

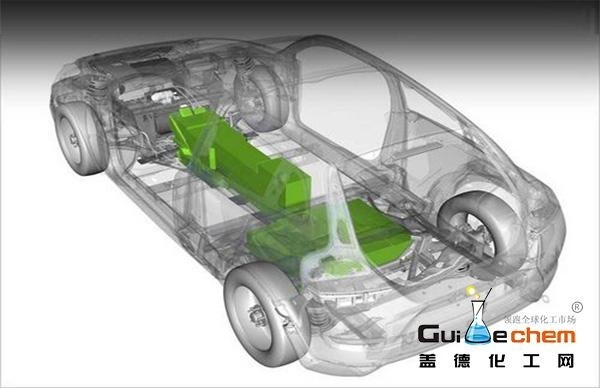

Battery materials are now a hot spot in the industrialization of research and development. Whether it is a cathode material or a carbon material in the anode, it has attracted much attention from the market. Among them, silicon-carbon anode material is a research and development hotspot. The different positive and negative materials and formulas of various manufacturers make the disassembly and recycling of power batteries face complex. It seems that the easiest is to lower the standard of use.

In the way of recycling and reusing car batteries, cascading utilization is currently the most important promotion method, because electric vehicles have quite high standards for battery density and stability. According to industry insiders, when the charging capacity reaches 80% and cannot continue to increase, the car battery is declared scrapped. And the scrapped batteries are more than enough for low-speed electric vehicles such as scooters and municipal emergency lighting.

The "Energy-saving and New Energy Automobile Industry Development Plan" requires that the cascade recycling of power batteries be strengthened, and the responsibilities, rights and obligations of all parties must be clarified in the management methods and system establishment. The government should not only guide battery manufacturers to recycle batteries, but also encourage the development of specialized battery recycling companies.

It can be seen that the recycling of electric vehicle batteries must extend the responsibility of battery manufacturers and build a recycling system. This field will also become a new opportunity for the development of innovative companies. In the construction of battery packs, they not only have to solve the impact of differences in battery performance due to different driver habits in the use of batteries in the car. At the same time, in terms of installation, a more unified interface and wire standard must be established.

Due to the strong downstream demand for new energy vehicles, the supply of power batteries will still continue. A person in charge of a company engaged in new energy investment told reporters that this phenomenon is expected to continue for one to two years, and the quotations of potential investors are rising.