Core competitiveness of leading brands

Since CSP heat transfer oil was successfully used in the first commercial CSP plant in California SEGS in 1984, its product components have been known to the public, and the production technology is no secret. But even so, there are still two major oligarchs in the global market, and there is no situation where many manufacturers share the market. What is the reason? According to the CSPPLAZA reporter, Dowtherm A's thermal oil market share in the global CSP market has reached 75%. The reason for having such a high market share is closely related to Dow's production process and quality control. It can be said that product quality control is the main reason why Dow's thermal oil is ahead of the CSP market. Chen Hao, technical service manager of Suzhou Solutia Heat Transfer Oil Co., Ltd., said that the essential properties of biphenyl-diphenyl ether heat transfer oil determine that its maximum use temperature is only 400°C. It is impossible to hope that its use temperature will be further improved, unless Found another heat transfer oil product that is more suitable for solar thermal power generation. But for 30 years, the production process of CSP heat transfer oil has been improving, and the service life and product quality have been improved step by step.

Domestic heat transfer oil breakthrough

CSPPLAZA believes that there may be three reasons why domestic heat transfer oil has not been able to compete with the two major brands of Dow and Solutia. First, Dow and Solutia developed CSP thermal oil products earlier. When the first wave of thermal power generation in the CSP market surged in the 1980s, they had already laid the technical foundation for their products, and they have quickly grown into thermal power generation products. Leading brand in the oil market; second, China’s CSP market has been slow to start, and domestic thermal oil manufacturers do not have much investment and R&D motivation for CSP thermal oil products; third, for CSP project developers, heat conduction Oil has a huge impact on the operation of the entire optical field system and the overall efficiency of the power station. For heat transfer oil products that have no track record, they dare not take risks, because once the product quality fails, it will cause huge losses to the entire system, even if there are some manufacturers Claiming to be able to produce this kind of heat transfer oil, because there is no track record, the project team dare not use it rashly.

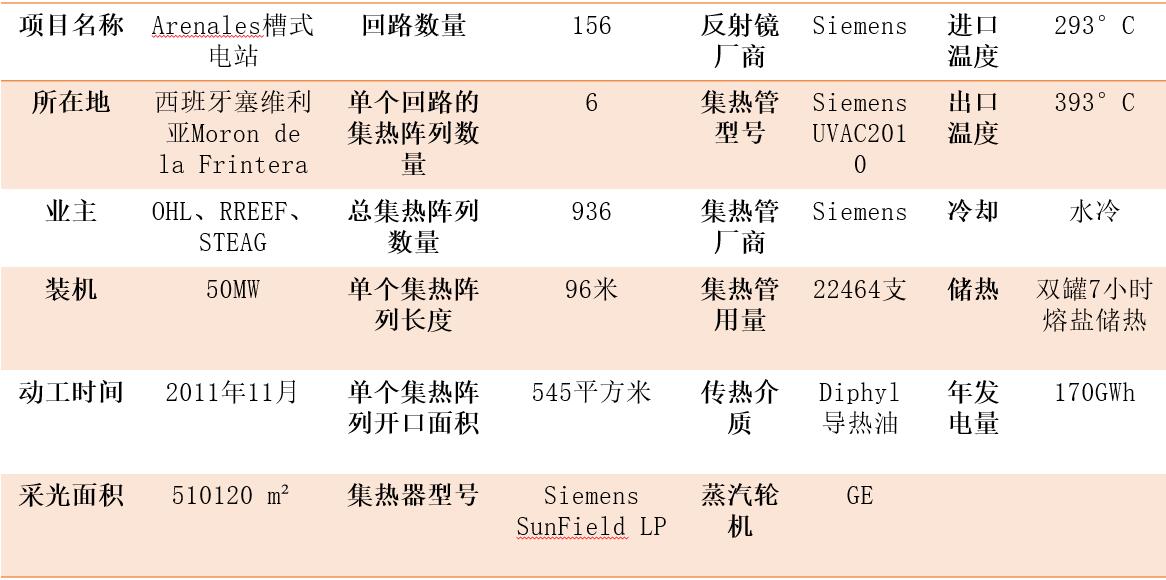

For this reason, domestic heat transfer oil brands should speed up the application of demonstration projects of their products while improving the quality of their own products, obtain the support of actual project operation data, and win the market with higher cost performance. Hanni Chemical’s hennytherm H1 heat transfer oil, as the designated supplier of Germany’s LANXESS heat transfer oil, began to serve Spain’s Arenales trough solar thermal power station in 2012, and it has been at the forefront in this regard.

The market will open its doors to outstanding domestic brands

With the gradual start-up of the domestic CSP market and the solar energy medium and high temperature heat utilization market, the quality of domestic thermal oil products has also continued to improve. As the domestic CSP project developers have stricter requirements for project cost control, the procurement price ratio is higher The domestically produced heat transfer oil will become its more rational choice. For domestic heat transfer oil manufacturers, if the product quality is good enough, it can compete with leading international brands, and then have a certain competitive advantage in price, domestic heat transfer oil brands will surely emerge in the domestic CSP Some gains in the market and even overseas markets. At present, many domestic thermal oil manufacturers are gradually turning their attention to the field of CSP. "In the future, China is likely to become the largest market for CSP in the world. We will give full play to our advantages in technology and localization to assist the development of domestic CSP projects with better products and better services. !"